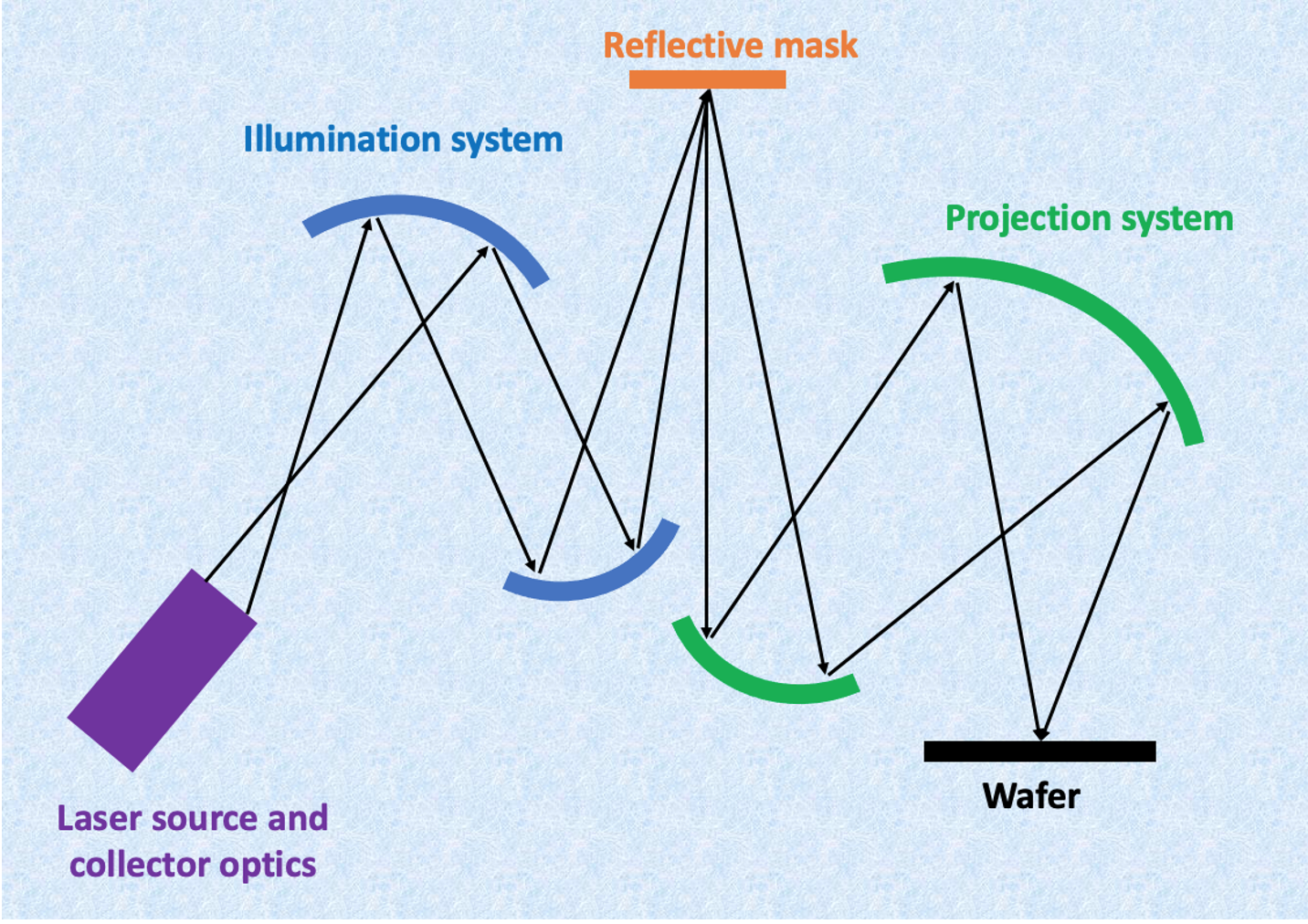

Extreme Ultraviolet Lithography (EUVL) is a projection lithography technology that uses extreme ultraviolet light with a wavelength of 13.5nm. In the illumination system, the target material is typically bombarded with light emitted by a high-energy laser. The target material is then ionized to generate high intensity plasma and emit extreme ultraviolet light. In this working band, the transmittance of optical materials is low, so the EUVL optical system (including the illumination and projection systems), needs to adopt a reflective structure. The schematic diagram of this optical system is shown in the figure on the left.

Extreme Ultraviolet Lithography (EUVL) is a projection lithography technology that uses extreme ultraviolet light with a wavelength of 13.5nm. In the illumination system, the target material is typically bombarded with light emitted by a high-energy laser. The target material is then ionized to generate high intensity plasma and emit extreme ultraviolet light. In this working band, the transmittance of optical materials is low, so the EUVL optical system (including the illumination and projection systems), needs to adopt a reflective structure. The schematic diagram of this optical system is shown in the figure on the left.

Light emitted by the illumination system uniformly illuminates the reflective mask. The mask pattern information is reflected into the objective lens of the projection system and the pattern is imaged on the wafer photoresist. The exposure of the entire mask is achieved by scanning.

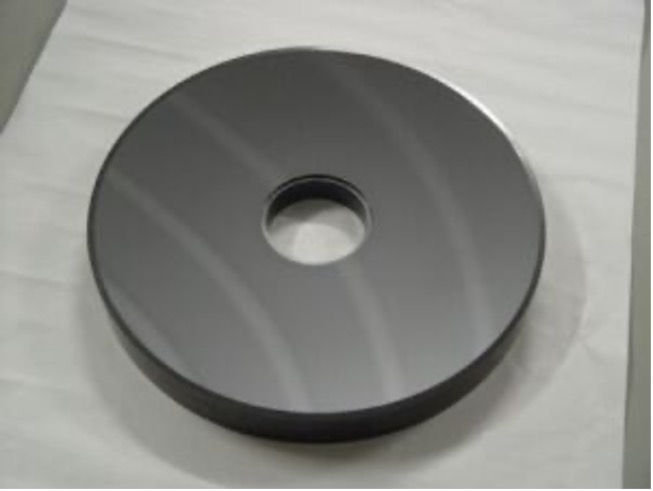

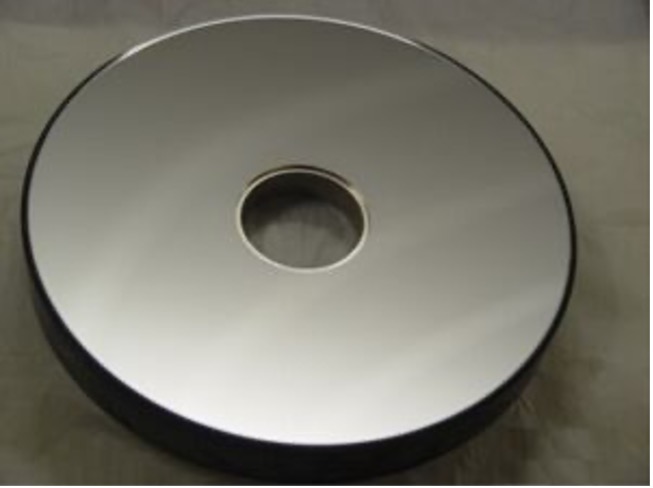

The mirror preparation required in EUV lithography is divided into two steps. One is to grind and polish the base surface of the mirror to the required surface shape and surface roughness, and the other is to coat the polished optical mirror surface. Multilayer optical films are employed which meet reflection requirements.

MLOptic can process ultra-smooth surface mirrors and thin-film coating preparation. We can also process on-axis and off-axis mirror surfaces up to 400mm in diameter. The RMS value of surface figure is better than 5nm, and surface roughness of the components is better than 0.5nm.

Sample mirrors shown below: